Bayside Laser Can Be Fun For Anyone

Table of ContentsMore About Bayside LaserBayside Laser Things To Know Before You BuyBayside Laser Fundamentals Explained9 Easy Facts About Bayside Laser Explained4 Simple Techniques For Bayside LaserHow Bayside Laser can Save You Time, Stress, and Money.

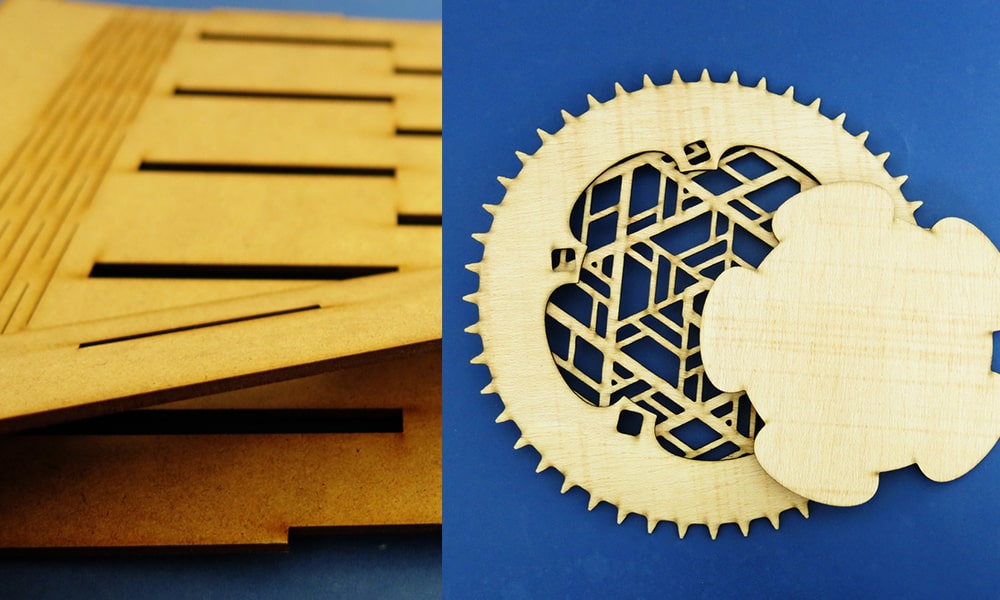

lasers excite as a result of how little sound they generate. lasers vaporise material through the packing as well as focus of light. This indicates no chips are created. That suggests offices stay clean and also hygienic. Your staff members do not after that have to tidy up chips, which makes the procedure considerably quicker as well as a lot more efficient.This suggests that the location around the cut stays undamaged, also with deep cuts. The material will certainly not be harmed or deformed.

Low-wear as well as low-maintenance laser cutting methods there is almost no loss of quality, as well as the outcomes constantly thrill with their optimum precision! (https://ba7sid3laser.bandcamp.com/album/bayside-laser).

Typical industrial processing needs some prep work prior to reducing the job piece. Operators will certainly do a series of challenging procedures such as measuring as well as attracting lines on the job item beforehand. This is a waste of time. The laser reducing machine utilizes computer system control technology to recognize cutting. After individuals go into the cutting program right into the computer.

5 Easy Facts About Bayside Laser Explained

Consequently, the laser reducing device can significantly reduce the processing time. Typical industrial processing devices mostly utilizes devices to process products. In regards to processing result, the cutting surface of the job item after cutting by the tool is rough and also uneven. For that reason, workers have to grind the product a second time.

The operation of reducing handling is simple. CNC laser cutters have little slits. It can perform challenging cutting of little parts.

The 6-Second Trick For Bayside Laser

DXTECH laser reducing machines can not only reduce various different products but additionally have great ease to utilize. If you need to know even more advantages of the laser cutter or various other elements of laser equipments, just call us.

In 1967, the British spearheaded laser-assisted oxygen jet reducing for metals. In the very early 1970s, this modern technology was placed right into manufacturing to reduce titanium for aerospace applications.

With a wavelength of just 1064 nanometers fiber lasers generate an extremely small area size (up to 100 times smaller sized compared to the CO2) making it excellent for cutting reflective metal product. This is among the main advantages of Fiber contrasted to CO2 - steel laser cutting. Fiber laser cutter advantages consist of:- Rapid handling times.

Bayside Laser for Beginners

Thaw as well as blow or combination cutting makes use of high-pressure gas to blow molten product from the cutting location, greatly lowering the power demand. Initially, the product is warmed to melting point after that a gas jet impacts the molten product out of the kerf preventing the need to raise the temperature level of the product any kind of further.

Brittle materials are particularly delicate to thermal fracture, an attribute made use of in thermal stress and anxiety breaking. A beam is concentrated on the surface area causing localized home More Help heating and thermal expansion.

The separation of microelectronic chips as prepared in semiconductor tool construction from silicon wafers might be performed by the supposed stealth dicing procedure, which runs with a pulsed Nd: YAG laser, the wavelength of which (1064 nm) is well adapted to the digital band gap of silicon (1. 11 e, V or 1117 nm). For every one of these, the axes of activity are usually marked X and also Y axis. If the reducing head may be managed, it is marked as the Z-axis. Relocating product lasers have a fixed cutting head as well as relocate the material under it. This approach supplies a continuous range from the laser generator to the workpiece and also a single point from which to remove reducing effluent.

This style of device has a tendency to have the fewest beam distribution optics however also tends to be the slowest. Crossbreed lasers offer a table that relocates one axis (typically the X-axis) and also relocates the head along the much shorter (Y) axis. This results in a much more continuous light beam delivery course length than a flying optic device as well as might permit a simpler beam of light delivery system.

The Greatest Guide To Bayside Laser

53 inches (3876 mm). Benefits of laser reducing over mechanical reducing include simpler work holding and also lowered contamination of workpiece (because there is no reducing side which can become contaminated by the material or pollute the material). Accuracy may be much better considering that the laser beam does not put on during the process.

With a wavelength of just 1064 nanometers fiber lasers generate an extremely tiny place dimension (approximately 100 times smaller compared to the CO2) making it ideal for reducing reflective steel product. This is one of the major benefits of Fiber contrasted to CO2. Fibre laser cutter advantages consist of:- Fast handling times.

Melt as well as blow or fusion cutting makes use of high-pressure gas to blow liquified product from the reducing location, considerably decreasing the power demand. Initially, the material is warmed to melting point then a gas jet blows the molten product out of the kerf staying clear of the demand to raise the temperature of the product any kind of better.

Breakable products are particularly delicate to thermal crack, a function manipulated in thermal stress and anxiety cracking. A light beam is concentrated on the surface creating localized home heating and also thermal development.

Not known Details About Bayside Laser

The separation of microelectronic chips as prepared in semiconductor tool manufacture from silicon wafers might be executed by the so-called stealth dicing procedure, which operates with a pulsed Nd: YAG laser, the wavelength of which (1064 nm) is well adapted to the digital band void of silicon (1. 11 e, V or 1117 nm) (laser cut tube). For all of these, the axes of movement are generally assigned X as well as Y axis. If the reducing head might be controlled, it is marked as the Z-axis. Relocating material lasers have a fixed cutting head and also move the material under it. This approach provides a constant range from the laser generator to the work surface and a single point where to get rid of reducing effluent.

This design of device often tends to have the least light beam delivery optics yet likewise has a tendency to be the slowest. Crossbreed lasers offer a table that relocates one axis (usually the X-axis) as well as relocates the head along the shorter (Y) axis. This leads to a more consistent beam of light delivery path length than a flying optic equipment and also may allow an easier light beam shipment system.